There are a number of ways to add color to an LCD. Since LCD's do not emit light, the color must come from polarizers, filters, inks, or auxiliary lighting. As is usual, the choice comes down to appearance vs. cost, with cost winning out in most applications.

Leadtek has approved blue, green and red colored transmissive front polarizers for use in indoor and outdoor applications. For instance, a reflective blue display exhibits medium blue segments on a bluish silver background.

It is also possible for volume custom LCD applications to have a multi-color screened image polarizer. The quantities necessary to justify this approach are extremely high, and the price is somewhat outrageous, however the resulting colors can be worth the anguish.

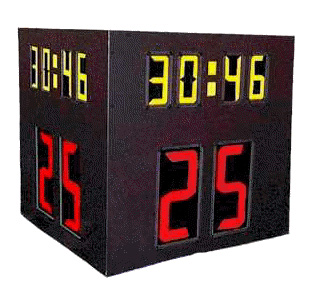

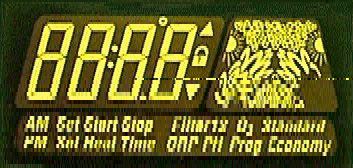

Colored inks (or colored filters) offer the greatest flexibility for colors in an LCD. The color inks are usually screened on the back (or sometimes the front) of the glass in the desired patterns. For example, a yellow transflector filter is very popular for both positive and negative image very large displays in outdoor message signs. Multiple colors are possible with multiple screen prints. The cost of this approach is the lowest and most adaptable. We recommend backlighting. under all lighting conditions.

|

|

The colors on these displays were applied to the rear of the glass with color inks. In addition, they are negative image displays with a black mask on the front that blocks stray backlight from "bleeding" through.